The Science Behind Neodymium Magnets: How They Work and Why They’re So Powerful

In the world of magnets, neodymium magnets are the rock stars. Despite their small size, they are the big hitters. The power and performance of neodymium magnets make them essential in everything from earbuds to electric vehicles. But what exactly makes these magnets so powerful? The answer lies in the unique properties of the elements that compose them and the science of their magnetic fields.

Neodymium magnets are a type of rare-earth magnet, which are the strongest type of permanent magnets available today. So, what are rare earth elements? Put simply, rare earths are a group of chemically similar elements with unique properties that make them invaluable in modern technology, despite the challenges associated with their extraction and processing.

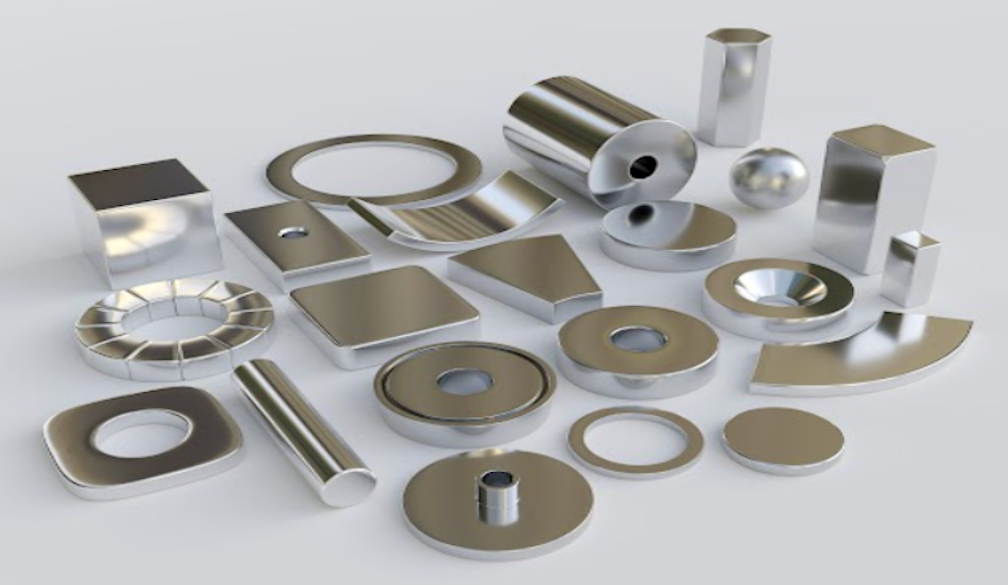

These magnets are made from an alloy of neodymium, iron, and boron, forming the compound NdFeB. Neodymium is one of the 17 rare-earth elements in the periodic table, but despite its name, it’s not particularly rare. While rare-earth elements are relatively abundant, they are not often found in concentrated deposits, making their extraction economically challenging.

First developed in the 1980s, these rare earth neodymium magnets have revolutionised many industries. Their strength, compact size and relatively low cost compared to other types of magnets, such as samarium-cobalt, make them indispensable in various applications.

How They Work: A Quick Lesson on Atomic Structure

To understand the power of neodymium magnets, you have to go down to the atomic level. Magnetism in any material arises from the motion of electrons around an atom’s nucleus. Neodymium magnets are particularly powerful because the neodymium atom has an unpaired electron in its outer shell. This electron creates a magnetic moment—a measure of its tendency to align with a magnetic field—that is much stronger than in other materials. When combined with iron and boron the result is an extremely strong magnet.

Turning Raw Materials into Magnetic Powerhouses

The production of neodymium magnets involves several complex steps. First, the raw materials—neodymium, iron, and boron—are melted together to form an ingot. This ingot is then crushed into a fine powder, which is pressed into moulds and sintered, a process where the material is heated without melting, to form a solid block. During this process, the material is exposed to a powerful magnetic field, which aligns the magnetic domains in the same direction, maximising the magnet's strength.

After sintering, the neodymium magnets are cooled, machined into the desired shape, and coated to prevent corrosion—a common issue with neodymium magnets due to their high iron content. The most common coatings include nickel, copper and gold, which protect the magnet and enhance its durability.

The key to a magnet’s strength lies in its magnetic domains. In a strong magnet like neodymium, the majority of these domains are aligned in the same direction, which means their magnetic fields combine to create a single, powerful magnetic field. This alignment doesn’t happen naturally—it requires a manufacturing process that carefully controls the material’s exposure to external magnetic fields.

Neodymium magnets have a high coercivity, which means they resist becoming demagnetized, even when exposed to external magnetic fields or high temperatures. This stability is another factor that contributes to their strength and reliability.

Neodymium Magnets - From Everyday Gadgets to High-Tech Innovations

The exceptional power of neodymium magnets has led to their widespread use in a variety of applications. In electronics, they are found in hard drives, headphones and microphones, where their strength allows for smaller, more efficient devices. In the automotive industry, neodymium magnets are crucial for the motors in electric vehicles, enabling compact yet powerful engines.

Neodymium magnets are also used in wind turbines, MRI machines, and even magnetic levitation trains. Their ability to generate strong magnetic fields with minimal material makes neodymium magnets ideal for applications where space and weight are at a premium.

Researchers are working on ways to reduce reliance on rare earth elements by developing new materials or improving recycling processes. However, for now, neodymium magnets remain the gold standard for applications requiring strong, compact and reliable magnets.

Neodymium Magnets - The Hidden Power in Your Pocket

Next time you use your headphones, swipe a credit card or drive an electric vehicle, take a moment to appreciate the science behind neodymium magnets. These tiny powerhouses are a testament to how understanding and harnessing the properties of elements at the atomic level can lead to remarkable technological advancements. Whether they’re in your pocket or powering the future, neodymium magnets are a perfect example of how science can change the world.

Neodymium Magnets Versus the Rest of the Magnet World

When comparing neodymium magnets with other types of magnets, several key factors come into play.

Magnetic strength is the first consideration. Neodymium magnets are the strongest type of permanent magnets available. Other magnets such as ferrite magnets are much weaker compared to neodymium magnets. Alnico magnets, though stronger than ferrite, still don’t match the strength of neodymium magnets.

Neodymium magnets are sensitive to high temperatures. They typically lose magnetism at around 80°C (176°F), though there are variants with higher heat resistance. Samarium-cobalt magnets perform better at higher temperatures and retain their magnetism up to about 300°C (572°F), making them suitable for high-temperature applications. Alnico magnets also have good thermal stability.

Neodymium magnets are generally more expensive than ferrite magnets but less costly than samarium-cobalt magnets. Ferrite magnets are the least expensive, which makes them popular for mass-produced products where high magnetic strength is not crucial.

Corrosion resistance is also a factor with neodymium magnets, which are prone to corrosion, particularly in moist environments and usually require a protective coating, such as epoxy, to prevent rust. Ferrite magnets are naturally corrosion-resistant and don’t require additional coatings. Samarium-cobalt magnets are also resistant to oxidation and corrosion, making them ideal for harsh environments.

Despite their strength, neodymium magnets are relatively brittle and can break or chip easily if dropped or subjected to mechanical stress. Ferrite magnets are more durable and less likely to chip or break. Alnico magnets are particularly tough and can withstand physical impacts better than neodymium magnets.

Due to their high strength, neodymium magnets can be made smaller and lighter while still providing a strong magnetic field. This is especially advantageous in applications where space and weight are limited, such as in consumer electronics. Ferrite magnets need to be larger to achieve the same magnetic strength, which can be a drawback in compact applications.

Neodymium magnets have high coercivity, meaning they resist demagnetisation. However, they are sensitive to high temperatures (>80°C) which can reduce their magnetic stability over time. Samarium-cobalt magnets have even higher coercivity and are highly stable, even in extreme conditions. Alnico magnets, while not as strong, have good magnetic stability.

Neodymium magnets are ideal for high-performance applications such as electric motors, hard drives, medical devices, and consumer electronics where compact size and high strength are crucial. Ferrite magnets are used in applications where cost is a significant factor, such as refrigerator magnets, loudspeakers, and low-cost motors. Samarium-cobalt magnets are used in aerospace and military applications due to their stability and high-temperature performance.

Understanding these factors helps in selecting the right magnet for the job.