CNC Workholding Methods: Find the Best Way to Load Your Workpiece for CNC Machining

One of the most overlooked aspects of CNC machining is workholding, which refers to how a workpiece is securely fixed in place during the machining process. No matter how advanced the machine is, if the workpiece isn’t held securely, the result won't meet the required accuracy or finish.

For industries in Brisbane that depend on CNC milling, machining or CNC turning, the proper workholding method can mean the difference between a perfect part and one that ends up in the scrap bin. Let’s explore the most common methods and consider what to look for when choosing the best option for your project.

Why Workholding Matters?

CNC machines are capable of extreme precision, but they can only do so when the workpiece doesn’t move under pressure. Cutting tools create vibrations, friction, and forces that can easily shift a poorly held part. Even the smallest movement can throw off tolerances or damage the surface finish.

Good workholding ensures:

- Accuracy: The workpiece stays in the exact position throughout machining.

- Safety: Both the machine and operator are protected from accidents caused by loose parts.

- Efficiency: Less downtime spent adjusting or correcting issues.

- Repeatability: Every part in a batch is machined in exactly the same way.

For workshops offering CNC machining in Brisbane, mastering workholding is just as important as having the latest equipment.

Common CNC Workholding Methods

There isn’t a single best method for every project. The right choice depends on the material, the shape of the workpiece, and the type of machining (milling, turning, drilling, etc.). Here are some of the most widely used methods.

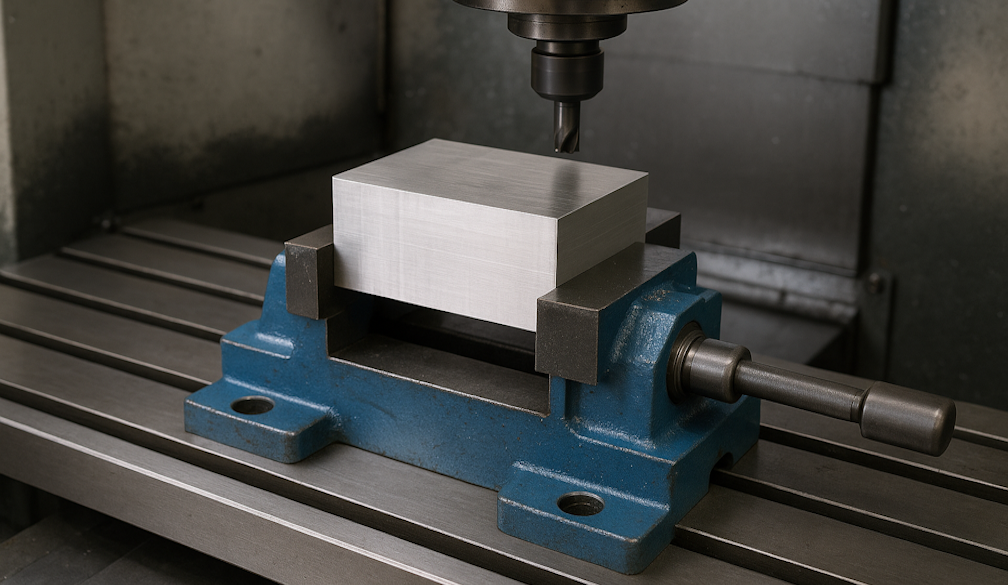

1. Machine Vices

Vices are one of the simplest and most common options for CNC milling machining. They use jaws to grip the workpiece tightly, holding it in place on the machine bed.

- Pros: Easy to use, quick to set up, good for flat or rectangular parts.

- Cons: Not ideal for irregularly shaped parts.

Vices come in different sizes and can be customised with soft jaws that match the part’s profile for a better hold. For many Brisbane machine shops, vices are the go-to option for everyday milling jobs.

2. Chucks

If you’ve ever looked into CNC turning in Brisbane, you’ve likely seen chucks in action. Chucks are essential for lathes and turning centres, where the workpiece rotates while the tool cuts. They grip the workpiece from the outside or inside, depending on the design.

- Pros: Reliable grip for round parts, essential for turning operations.

- Cons: Limited to circular or symmetrical workpieces.

Chucks can be manual or powered, with three-jaw and four-jaw versions available depending on the required precision and flexibility.

3. Collets

Collets are similar to chucks but offer greater precision. They’re used to grip smaller, cylindrical parts with even pressure around the entire surface.

- Pros: Very accurate, great for small-diameter parts.

- Cons: Limited range of sizes, not suitable for larger workpieces.

In CNC machining, collets are often used in both milling and turning applications where repeatability is critical.

4. Fixtures

Fixtures are custom-built workholding devices made to hold specific parts. They can be designed to secure irregular shapes, hold multiple parts at once, or provide access to multiple sides of a workpiece.

- Pros: Highly versatile, ideal for complex or repeat jobs.

- Cons: It can take time and money to design and build.

Fixtures are particularly useful in production environments where the same part is machined repeatedly. For Brisbane workshops that handle batch runs, fixtures can save significant time.

5. Clamps

Clamps are another simple method of workholding. They hold the workpiece directly against the machine bed or a fixture. They come in different styles, strap clamps, toe clamps, and edge clamps, to name a few.

- Pros: Affordable, adaptable, quick to set up.

- Cons: May obstruct toolpaths, not ideal for all shapes.

Clamps are often combined with other methods for extra stability.

6. Magnetic Workholding

Magnetic plates or chucks use strong magnets to hold ferrous materials in place.

- Pros: No mechanical clamps to block toolpaths, quick to load and unload.

- Cons: Only works with magnetic materials like steel or iron.

This method is especially handy for thin or delicate parts where clamping could distort the shape.

7. Vacuum Workholding

Vacuum systems use suction to hold flat workpieces securely against the machine bed.

- Pros: Great for thin, flat materials, no obstructions on the surface.

- Cons: Limited holding power, not suitable for heavy cuts.

Vacuum workholding is popular in industries where lightweight sheet materials are common.

Choosing the Right Method

So, how do you decide which method is best? A few factors come into play:

- Shape of the part: Round parts work well with chucks and collets, while flat parts are better suited for vices or vacuum systems.

- Material: Non-magnetic materials can’t be held with magnets, while very thin materials may deform under clamps.

- Operation type: CNC milling machining often uses vices, clamps, or fixtures, while turning almost always relies on chucks or collets.

- Batch size: For one-off jobs, simple methods like clamps or vices are fine. For production runs, custom fixtures can save time.

CNC Workholding in Brisbane

Here in Brisbane, industries like mining, aerospace, defence, and medical rely heavily on CNC machining. Whether it’s CNC turning in Brisbane workshops for round components or CNC milling machining for complex geometries, the choice of workholding plays a huge role in delivering precision and reliability.

At MK CNC, we understand how important workholding is to the final result. Our team uses a mix of proven methods and custom setups to make sure every job meets the required tolerances. From one-off prototypes to high-volume production, we take care in selecting the right approach for each part.

Final Thoughts

Workholding may not always get the spotlight, but it’s one of the most important parts of CNC machining. A secure and reliable setup ensures accuracy, consistency, and safety while keeping jobs on schedule.

Whether you’re exploring CNC machining for a new project or looking for a partner who understands the finer details, it’s worth working with a team that knows the importance of proper workholding.